TRULY MULTI PURPOSE!

Slot, Ramp, Plunge, Profile with one tool!

SUPERNOX

Best In Class!

High Performance Vibration & Chatter Free Endmills

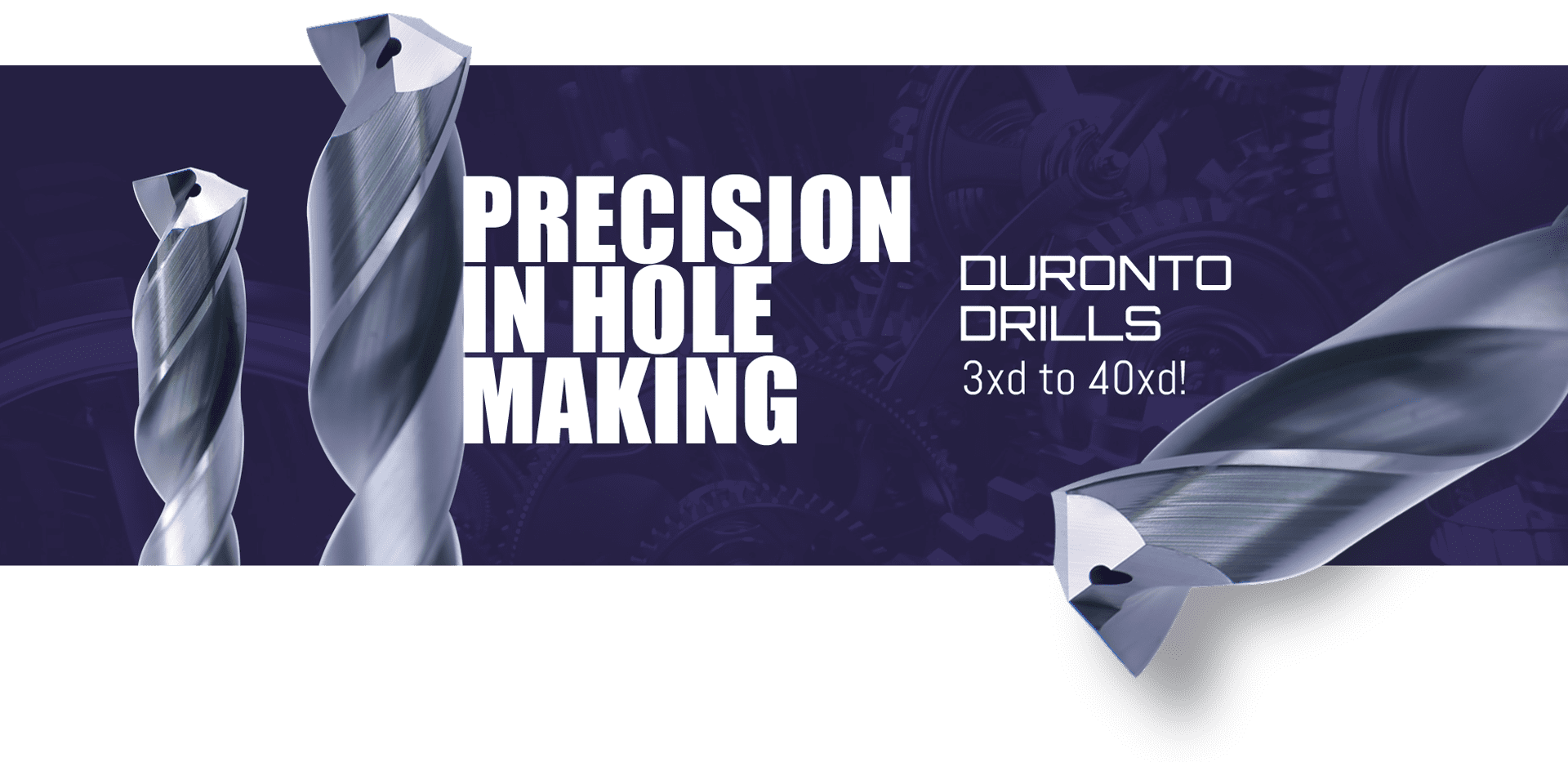

PRECISION IN HOLE MAKING

DURONTO DRILLS

3xd to 40xd!

Situated over 3 Acres at Falta Special Economic Zone, West Bengal, India,

NMC has the advantage of being within close proximity to Air and Sea Ports. Our Manufacturing Unit comprises of a complete Swiss CNC Tool & Cutter Grinding Setup along with dedicated Transor Filtration systems in a temperature-controlled environment for consistently manufacturing high precision cutting tools.

To backup the manufacturing, our Inhouse Engineering team uses advanced softwares to deliver new innovative solutions. Within this division, tools are continuously perfected to complement the constant technological

transformation in the metalworking industry.

To backup the manufacturing, our Inhouse Engineering team uses advanced softwares to deliver new innovative solutions. Within this division, tools are continuously perfected to complement the constant technological

transformation in the metalworking industry.

Consistent Manufacturing is aided by Quality Checks using the Zoller Genius 3M and Zoller measuring machine and Marcel Aubert Optical Measuring System. These instruments ensure that the precision tools are meeting the tight tolerance levels.

All tools are individually inspected and statistical process controls are carried out to constantly monitor production processing for possible corrective actions.